To get a better understanding of how you can use these manufacturing processes, that is, the 3D printing for injection molding, you have to be familiar with the terms. Read on as we dive into the meaning of injection molding and 3D printing.

There are various 3D printing trends in 2022 and polymers are the materials that are used most in these manufacturing processes. We will also discuss how you can use 3D printing for injection molding.

What is Injection Molding?

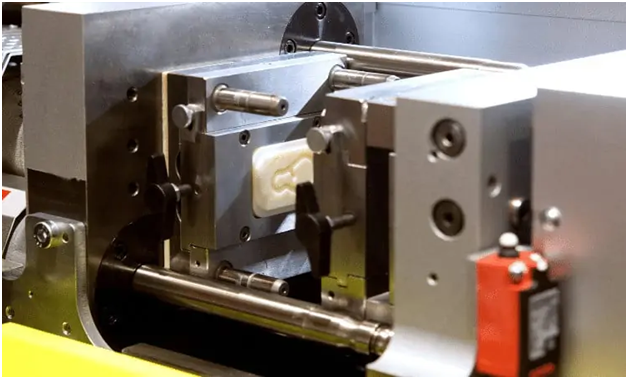

Injection molding is basically a manufacturing process that actual involves molding. It is mainly about injecting plastic into a mold cavity by heating it. However, that does not mean it is not implemented on other materials. You can check 3ERP injection molding for more information.

After being heated, the plastic is then fitted into the mold cavity. As it cools, it gradually takes the shape of the mold. The outcome is then ejected from the mold. That is why this whole process is known as injection molding because it entails injecting material into a cavity for molding.

Applications of Injection Molding

One of the various ways that injection molding can be used is that it is used to make solid designs that require it to be in a particularly continuous shape. It is used to smooth finishes for products that are integrated into other parts to reduce friction. It is the best method to use especially when you are producing identical products that are needed in large batches.

What is 3D printing?

3D printing on the other hand is a manufacturing process that implements a 3D printer that uses a computer-generated design to come up with a certain object or product. The designs are made prior via a computer program, then they are uploaded onto a 3D printer. then the model design is converted into an actual physical object by the 3D printer from the raw material that is fed into it.

3D printing is in various forms. The traditional 3D printing processes involve building objects, one layer at a time by depositing the manufacturing material onto a surface that is designed for that purpose. 3D printing can also be used for melting powder substances using high heat, a process that merges the powdered particles together into one end product.

Applications of 3D Printing

Unlike injection molding, 3D printing is used for small-batch production and prototyping techniques. The most significant is in its intricate designs since they contain holes and gaps at the center. The design of a 3D printer changes from time to time even during the production stages.

How To Use 3D Printing For Injection Molding

3D printing can, in fact, be used for injection molding but it cannot completely replace the functionality of injection molding for a number of reasons.

First of all, injection molding requires its own specific machinery. Also, compared to 3D printing, it is considered to be more efficient and faster, and with very precise dimensions that produce smooth finishes.

However, 3D printing is evolving as time goes by. This is why it is possible to use 3D printing to perform some of the injection molding purposes. In order for you to use a 3D printer for injection molding, there are things you have to keep in mind.

What is the Compatibility Standard of Your Object With 3D Printing?

The object you are using has to be compatible with 3D printing. You have to know the number of moving parts your object has, the number of pieces required at the end of the process, uniformity in terms of shape and size, and the surface that is available for use during the printing process.

Once you have all these things figured out, you can proceed to the next step. If you are not certain of all the above-stated requirements, it is recommended that you print out a few individual samples which you can use as samples.

Create A Mold

Usually when injection molding, the first step is to create a mold. However, this process can prove to be quite complicated. Not to worry though because some of the software contain scripts that can simplify this process for you.

If you decide to manually undertake some of these steps, you will be required to remove the pre-set internal structures that were being used earlier. Lower the face count so as to make your object a lot less complex. You can further reduce the poly count to make the process far much easier.

To prevent the prints from sticking, in your next step, add a few drops of oil to the mold. The oil will make it easier for you to remove the end product from the mold without struggle.

Fill The Material Into The Mold

You can opt to program your 3D printer to fill in the mold with your material of choice, or you can do it manually. Using a printer is preferable because of precision since you do not want to fill it too much or too little.

Using the 3D printer will enable you to create a small but effective assembly line. This way, you can produce larger batches, sometimes even in dozens if the designs are smaller in size.

Other Factors To Consider When Choosing Between 3D Printing and Injection Molding

Before you decide touse 3D Printing for injection molding, it is important that you consider the following factors and find out what best suits your production needs.

Production costs

3D printing is more cost-effective when producing runs, that is, from one to a hundred pieces. On the other hand, injection molding is most appropriate for when you are producing large batches. It is important to recognize that you require custom metal molds for you to implement injection molding.

Production Schedule

3D printing is known to have quite a short lead time compared to injection molding. However, 3D printing is much slower. On the other hand, injection molding is much faster, especially after the tooling process is complete and set to use.

Product Shape Complexity

If your product design has a more complex shape, it may not be appropriate to use injection molding in this case. 3D printing is the opposite since it is capable of designing products with much more intricate structures, and products with gaps and spaces.

End Product Finishes Required

For those products that are not necessarily needed to have smooth surfaces, then 3D printing is the best in such a case. This is because 3D printing produces designs that are slightly rough. For those products that have to have smooth edges, however, injection molding is most appropriate since it uses very minimal friction in its processes.

Product Durability

For those products that are manufactured with the 3D printing manufacturing process, it is important to note that when the layers are merged together, they may get weak in the process. So injection molding would be preferable when you want a stronger end product that is produced in a single step.

Final Thoughts

It is possible to use 3D printing for injection molding. However, you have to weigh your options on factors that influence either of your choices. We hope this text will help you in deciding whether or not to go for 3D printing.

No comments:

Post a Comment