Holographic beam samplers are diffractive optical elements that take a small fraction of the energy of an input beam and diffract it, creating new sub-beams in addition to the input beam . The resulting diffracted sub-beams have the same characteristics as the original beam, but their angular direction will be different.

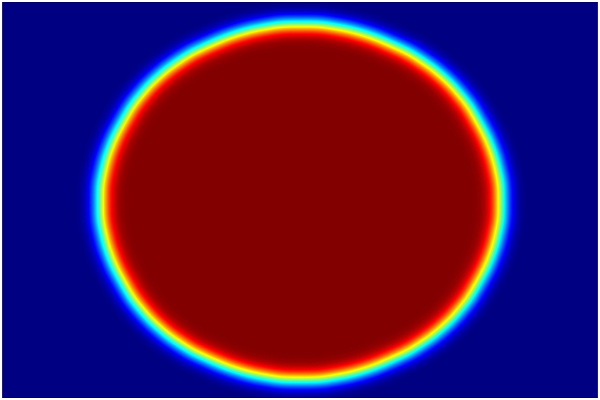

The beams coming out of the holographic beam sampler are referred to as diffraction orders. The main beam is called the zero order and is the beam that goes unaffected by the presence of the diffractive optical element. The extra beams are the +1 and -1 diffraction orders. There can be more diffraction orders but in a holographic beam sampler it is practical to utilise only those two.

The holographic beam sampler is very useful in those applications in which a beam parameter needs to be monitored constantly, but at the same time the main beam cannot be altered in any way by the probing system. Thus, with the holographic beam sampler, parameters like beam power or wavefront error can be constantly monitored on one of the extra beams. Given that in terms of beam parameters the relation between the main beam and the extra beams is deterministic, it is straightforward to translate the parameter values from one beam to the other.

The power ratio between the first order and the zero order is referred to as the sampling ratio of the diffractive optical element. It is a function of the operating wavelength and the step phase difference on the diffractive beam sampler element. This means that by tuning the step or height of the sampler, the sampling ratio can be adjusted. The power landing on the plus one or minus one order can be sufficiently low such that the losses along the zeroth order, that is, the main beam, are kept to the minimum. In high power lasers, this is a convenient approach to attenuate the sampler energy sufficiently so it does not harm the sensor.

Also Read- What is USB-C charging? Everything you need to know about the new USB

When using the plus one order as the probing beam, the minus one order can be simply blocked with a beam dump to avoid diffuse light in the system. The information obtained with the plus one order can be quickly processed and used as feedback to the control system in such a way that the proper commands can be used at the laser driving system and laser power supply so the laser spot stays stable over the entire process.

Laser systems using this type of beam sampler benefit from the fact that the holographic element is very thin and lightweight, and has a high laser damage threshold . As such, its implementation does not penalise the overall volume and weight of the system and it is easy to integrate.

GiftWifts by Leopards Courier Services is Pakistan’s top-ranked gifting service provider.

ReplyDeleteSend Gifts Online